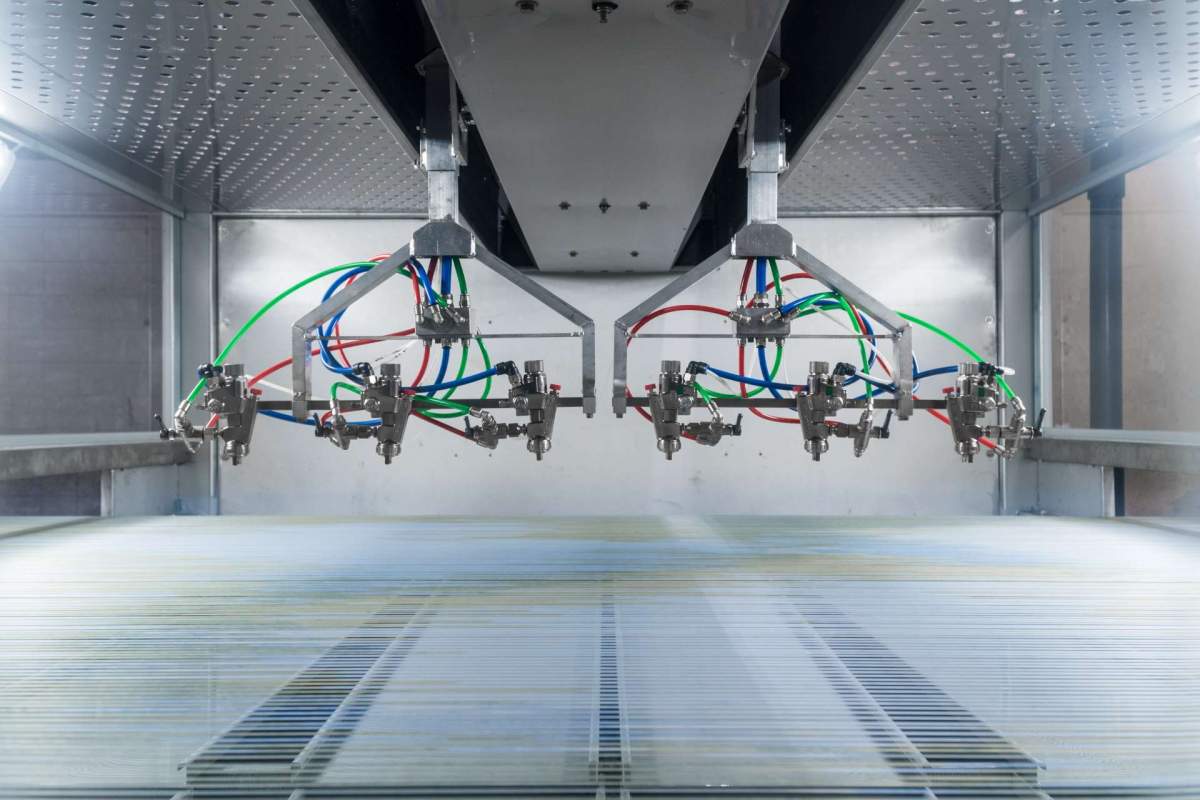

The automatic reciprocating spray booth features an innovative mechanical system for the movement of the two carts set against each other to support the guns. The use of special linear guides moved by a high-performance toothed belt and an engine managed with a specific action, allows the two carts a translation velocity that until a short time ago, would have been unthinkable. The simplicity and robust of the system, coupled with an electronic management of movement, guarantees excellent reliability and precision of use, even in particularly harsh environments such as that of tanneries. The performance assured by this new booth guarantees a better spray quality than can be attained with any alternated spray booth produced up until now. All this with very little maintenance and absolutely no vibrations.

FEATURES

- Structure entirely made of stainless steel.

- Strong structure complete with perforated top skies designed to optimize the air flow necessary for proper suction.

- Uniform and optimal distribution of the air.

- Pressurization system that offers the option of direct inlet of filtered and conditioned air inside of the spray booth, taking it directly from outside of the finishing room. The advantages of this system are the filtering and conditioning of the air that enters the booth, the reduction of the depression present in the room used for the finishing, the best suction with consequent reduction of the overspray and the lower environmental impact with consequent improvement of the microclimate within the finishing department.

- Large glass surfaces to facilitate monitoring of the spray process.

- Internal structures, fed by the spray aerosol, are constantly kept washed through recirculating water veils (or dry filtering when requested).

- Easy maintenance and internal cleaning.

- Direct air regulation and atomization air unit in ergonomic position.

- Control unit located on the front of the cab with vision and control in optimal position.

- Reliable mechanics with high performance designed for any spraying equipment (conventional, airless, airmix, HVLP, LVLP). Predisposition for low pressure spraying system with precise regulation for air atomization with working pressures up to 0.2 bar.

- High productivity thanks to cart speed.

- Adjustable translation velocity according to working requirements, controlled directly by the commands on the front of the booth.

- Direct paint distribution from the pump to the gun (system without paint distributor).

- Homogenous colour distribution throughout all points of the belt.

- Possibility of installing up to 6 guns (3 per cart) with two finish supply circuits.

- Manual sprayguns height adjustment system.

- Chemical product flow regulators to guarantee homogeneity of product entering the guns.

- HVLP spraying guns with high transfer efficiency for overspray reduction with consequent reduction of pollutant load and time savings in cleaning inside the cabin.

- The paint distribution circuit provides, on all models, the possibility of product recovery and circuit cleaning in a short time by pumps. The product still present in the circuits when the processing has come to an end is recovered with a consequent decrease in the pollutant load and dispersion in the cabin and consequent decrease in production costs.

- Last generation spraying control system complete with transport encoder, carrousel encoder, scan bar up to 5 mm pitch.

- Complete plant “Control System” with package 4.0 for saving, storing and recalling work recipes (all parameters including drying phase).

- “Energy Saving” system for energy saving and speed control of each motor by inverter.