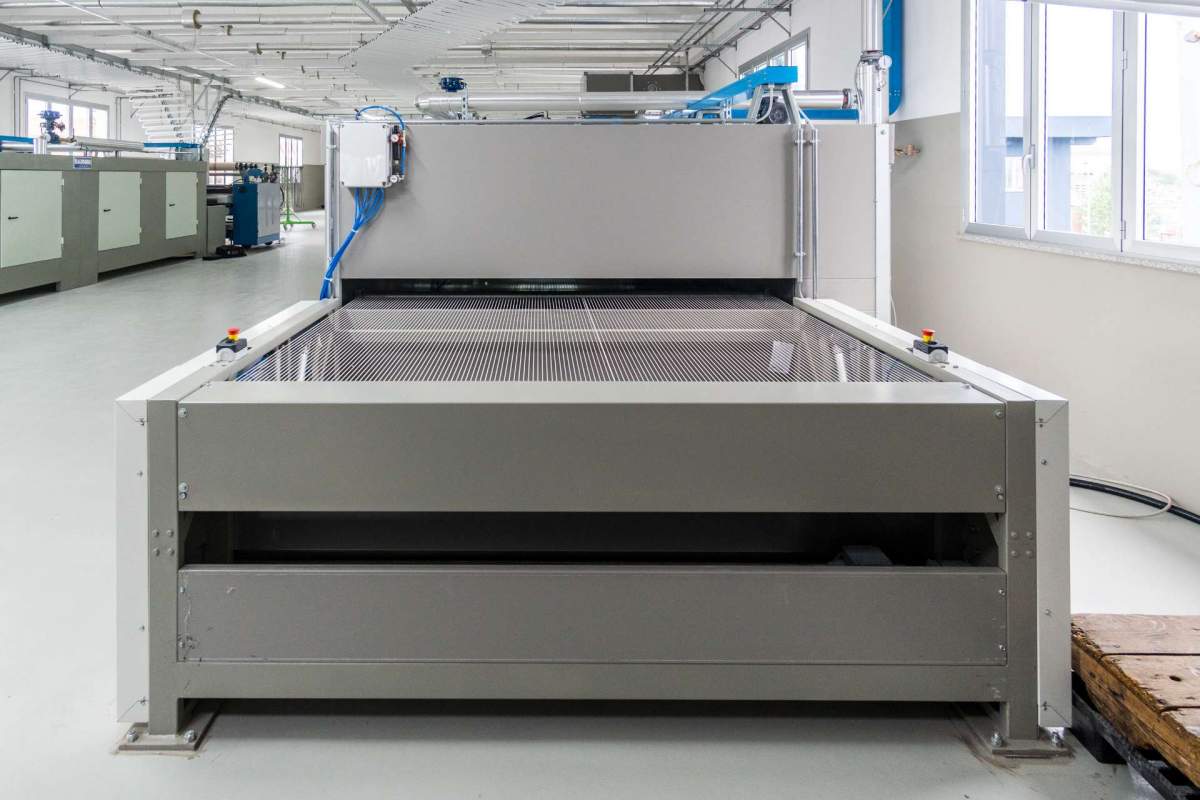

The drying tunnel model TV is designed with the goal of creating an easy construction, installation and maintenance.

The capacity and reliability of operation that distinguish it led to a significant appreciation of our customers with more than a thousand positive references worldwide. The structure is divided into variable-length items to 1.5 or 2.0 meters and it is able to meet all production requirements and installation.

The tunnel can be supplied by various energy sources such as steam, hot water, superheated water, electrical heaters and diathermic oil.

- Structure completely manufactured in die-cast galvanized sheet metal.

- Pre-painted panels with high density insulation self-extinguish, thickness 40mm.

- Fans with large surfaces for air filtering in circulation.

- Conveyor belt support rollers equidistant from one another and adjustable in height.

- Large sized front and rear doors for easy internal inspection and maintenance.

- Radiators in stainless steel.

- Centrifugal Exhaust fan.

- Electronic thermoregulator.

Optional:

- Inverter to adjust inner ventilation.

- Humidity control.

- Heat exchangers to recover the exhausted air coming out from the tunnel (Heat Recovery System).